What is COB LED Technology?

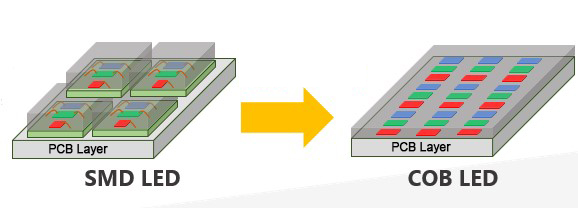

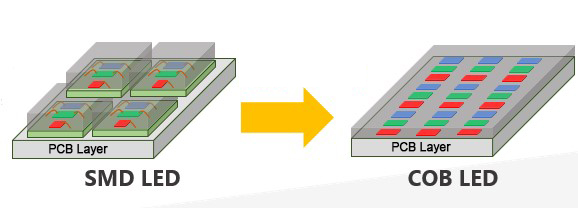

Chip on board (COB) technology is a method of directly mounting red, green, and blue chips onto a printed circuit board (PCB). Packaging the bare chips directly onto the PCB enables a much higher chip density while creating a flat uniform LED surface. The combination of three-color values allows the chips to achieve a higher color gamut and replicate true-to-life imagery.

In other words, with COB LED technology, the number of LEDs that can be placed in any given area of a display is way higher than with other LED packaging approaches, such as Surface Mounted Diode (SMD) and Dual in-line Package (DIP).

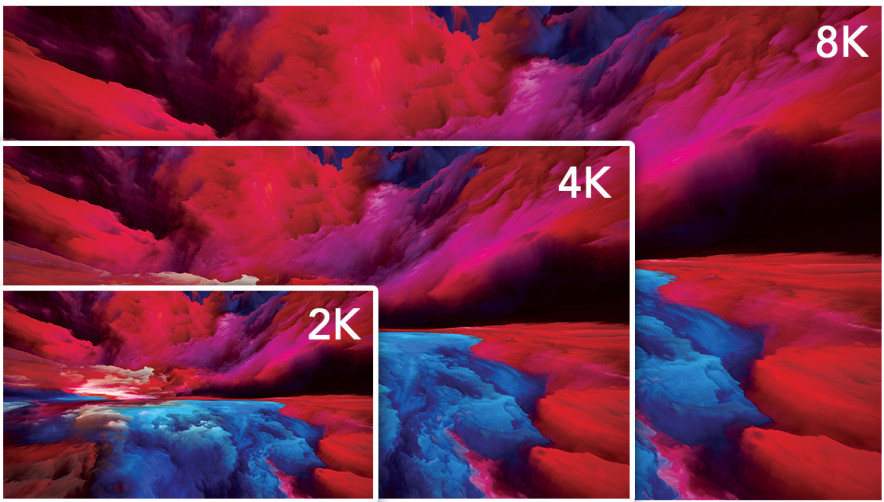

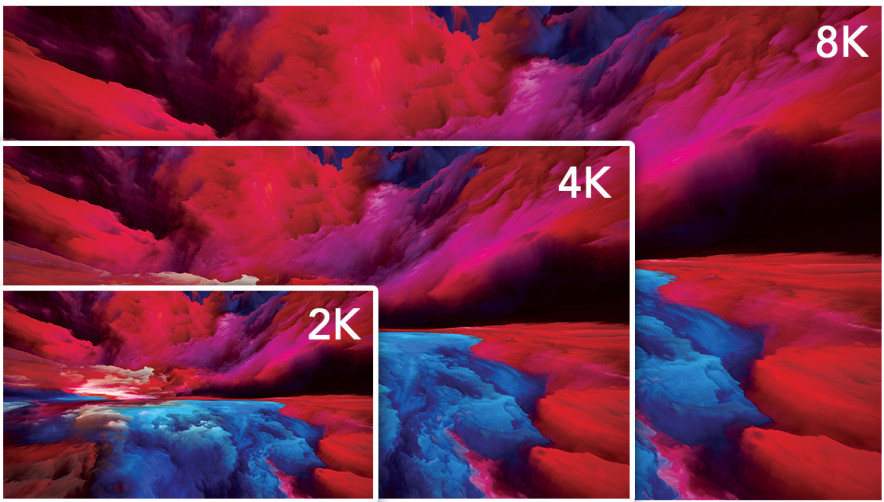

Occupying less space on the board without any bonding wires allows for a tighter pixel pitch. The tighter the pixel pitch, on the other hand, the higher resolution. This is one of the reasons behind COB’s breakthrough in the LED packaging world. The potential of improving image quality, reliability, and energy efficiency of a display is huge and will be only further explored in various future applications.

SMD vs. COB Packaging Technology

Before the emergence of the latest COB LED technology, display devices using LEDs relied on other LED packaging processes. The two most common types were SMD and DIP. As the SMD offered superior density and array power, it quickly emerged to be the most popular choice for LED displays.

SMD technology works by using bonding wires to mount the components on the surface of the PCB. This is done using a soldering machine that applies heat and pressure to the joints to create a permanent connection. While this initially represented a major improvement over other techniques, if the soldering is not controlled accurately properly, there’s a bigger risk of weak points in that connection. They may be too weak or too strong, leading to failure.

Besides, SMD components are more susceptible to damage from external factors such as heat and humidity or collision. Since the components are mounted on the surface of the circuit board, they are exposed to the environment and can be easily damaged by external factors.

In contrast, COB technology involves bonding the components to the circuit board using an adhesive, which can provide a more robust and reliable connection. This makes COB technology less susceptible to failure due to external factors and soldering issues. Not needing the bonding wires is also what enables a finer pixel pitch.

Finally, SMD technology is generally limited to components that are larger than 0.5 mm, while COB technology can be used with much smaller components, down to a few micrometers in size.

COB LED Advantages:

Robust Pixel Durability, Wider Viewing Angles

Ultra-High Contrast Levels, Ability to achieve ultra-high pixel densities

Resistance against moisture, dust, static discharge, UV light, and minor liquid surface contact.

Lower thermal output, supporting longer life, Reduced Power Consumption without compromising brightness